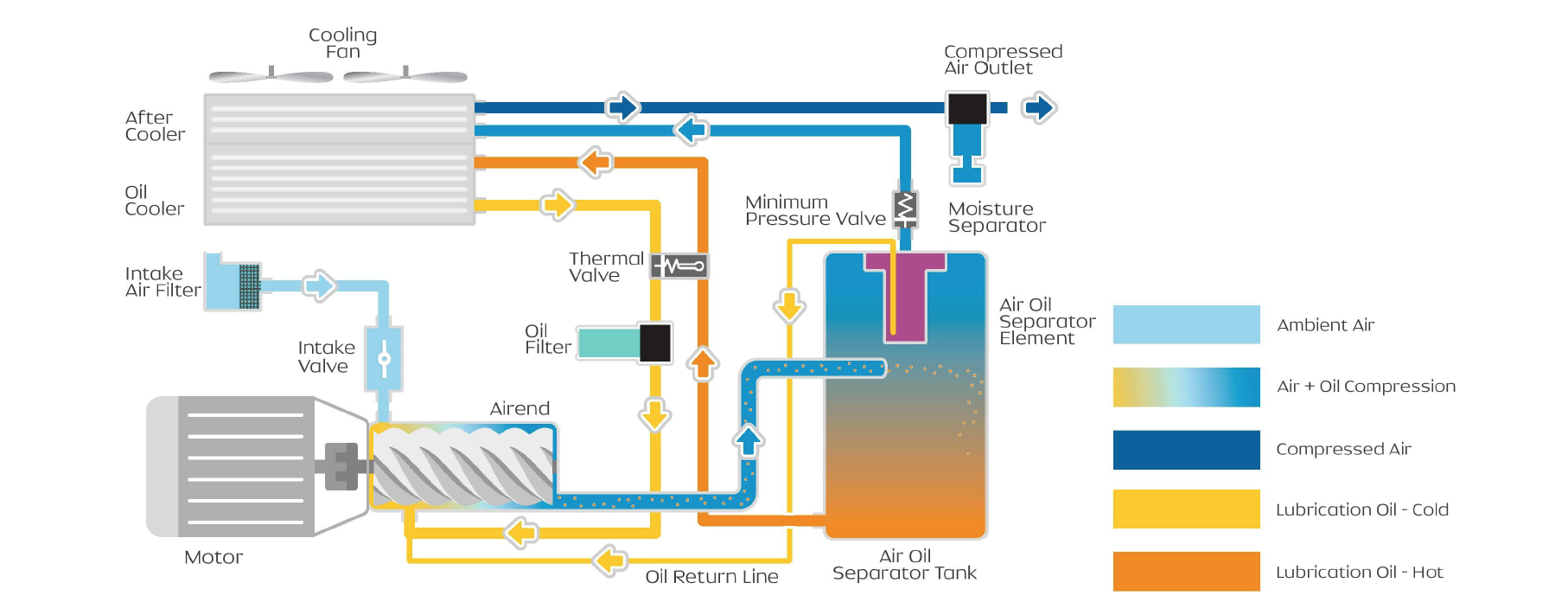

Air Oil Separation Process:

After the air is being compressed in an oil flooded compressor, the air oil mixture enters with high velocity into the Air Oil Separator tank. Here it undergoes a unique and efficient 3 stage separation process which removes the maximum oil content.

This process uses the impact velocity of the air oil mixture, along with centrifugal action – making the mixture very lean.

The final stage of this separation consists of passing the lean mixture through the Air Oil Separator.

What is an Air Oil Separator?

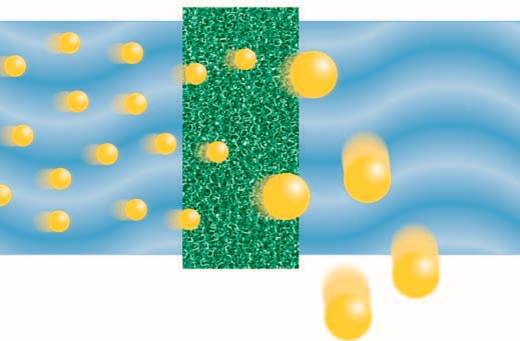

An Air Oil Separator is a filter which separates the oil from compressed air. Thus leaving the compressed air with an oil content of < 1 ppm.

Air Oil Separation done by a coalescent media (separator element)

Importance of Air Oil Separator:

An Air Oil Separator plays a key role in the separation process. It ensures that only the air and no oil is delivered to the outlet. Hence it is important that the separator should be replaced from time to time. Care should be taken that an authentic separator needs is used.

Following is the significance of on time replacement and use of genuine separators.

Importance of On Time Replacement:

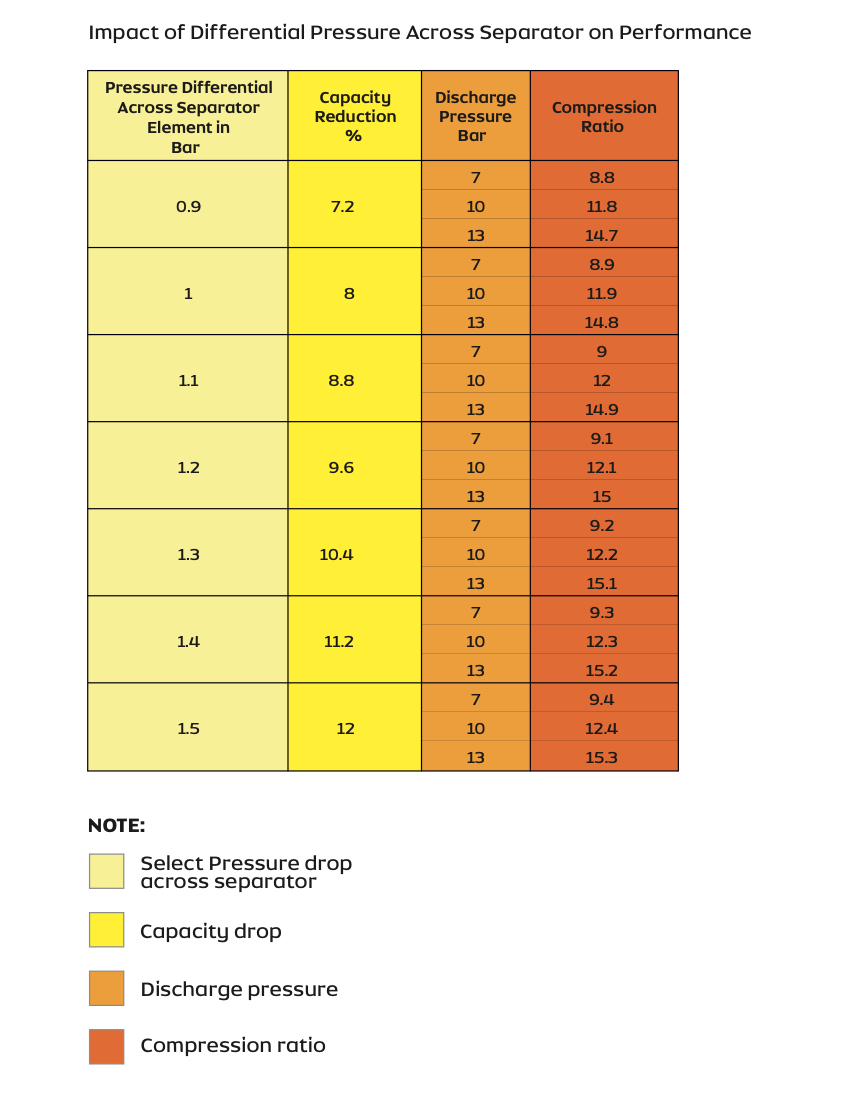

- Pressure drops across the separator:

Pressure drop increases due to prolonged use and use of poor-quality separator. The pressure difference across the separator element directly converts to power cost.

- Additional cost and change in system:

The compressor capacity decreases due to flow restriction by clogged separator element. It can even reach a point of 12% in extreme conditions.

The compression ratio of 7 bar machine increases to 9.64 (extreme condition). At this ratio, the load on bearings will be quite high! .

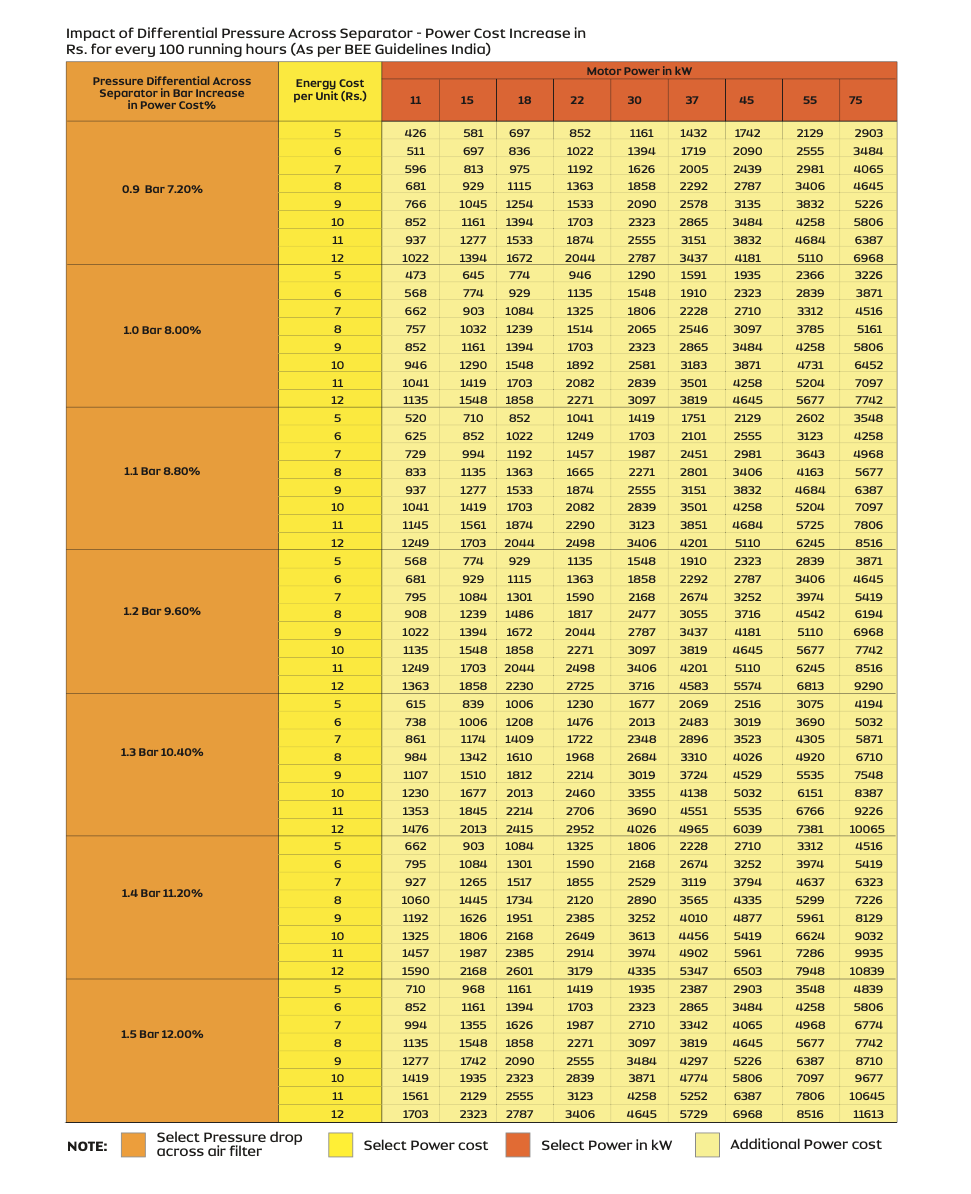

A 30-kW compressor will cause you an additional power cost of INR Rs.5000, due to separator replacement delay by just 10 days of continuous operation. Timely replacement can avoid this unnecessary expense.

Importance of using genuine Air Oil Separator:

- Safety hazard:

Usage of inferior quality parts will result in serious damage, including the possibility of a fire accident.

Inadequate earthing can cause a separator to collapse (25% risk). It may causes fire and may also destroy the entire machine.

- Reduced machine performance:

Spurious separator leads to additional resistance for air flow. It creates more pressure drop and thus puts additional load on the motor. Inadequate separation deteriorates air quality, reduces performance, and damages the downstream components.

- High power consumption:

Due to dense in filtration media, additional pressure drop is created.

This causes additional power consumption. Every 1 bar (14.5 Psi) of pressure drop results in ~ 7% additional power consumption.

Refer the table below for impact of Differential Pressure across the separator on performance.

Do you want to know more on the importance of an Air Oil Separator?

Contact our experts who will guide you further.